-

TISSUE MAG ARTICLE

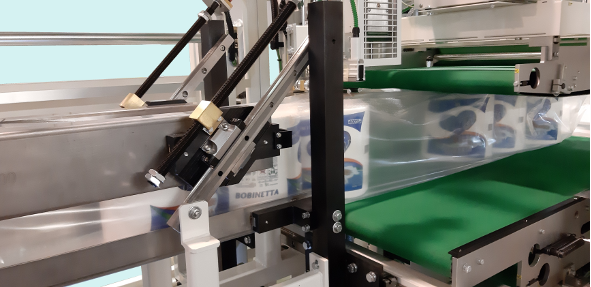

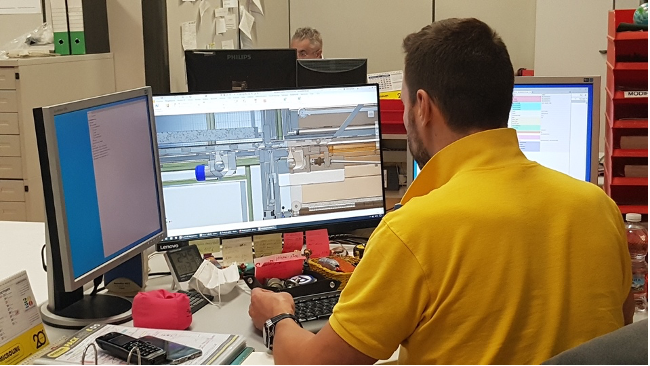

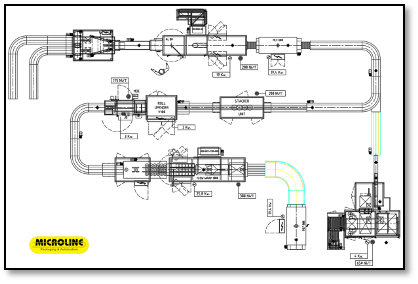

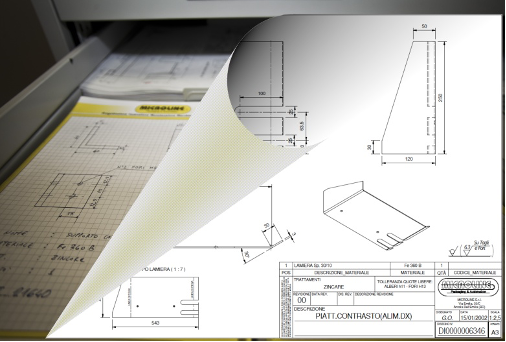

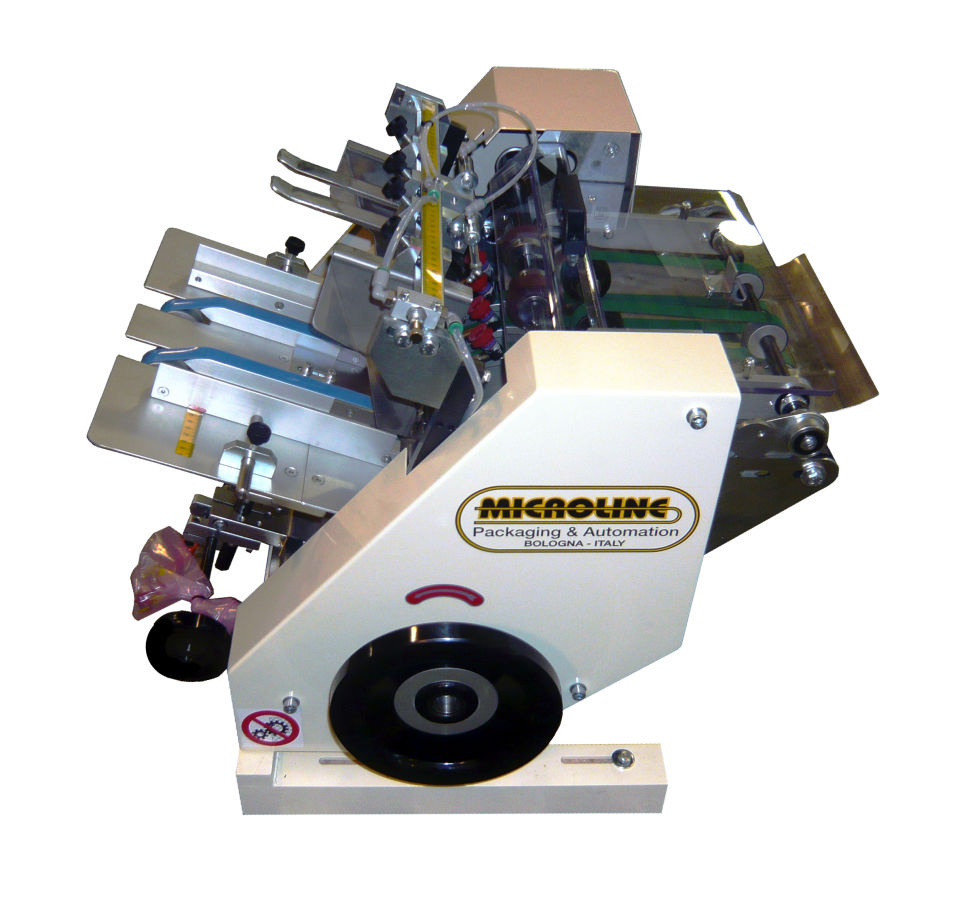

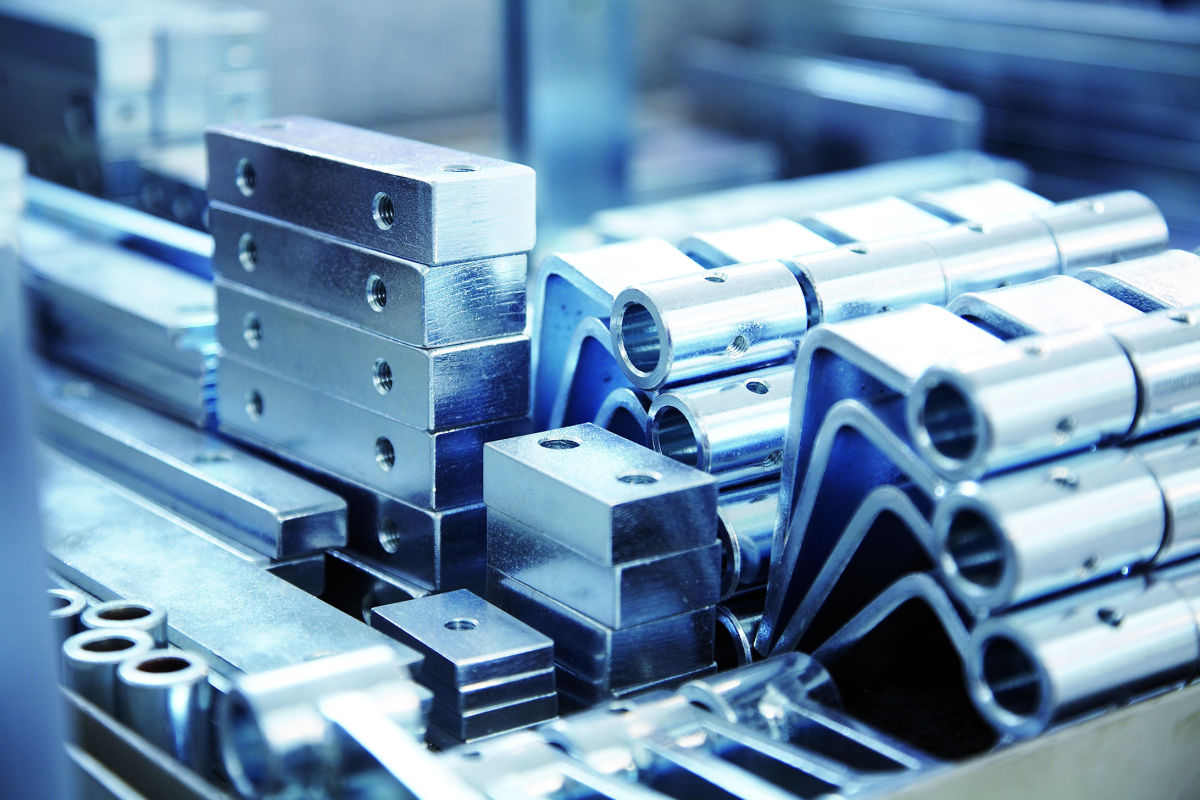

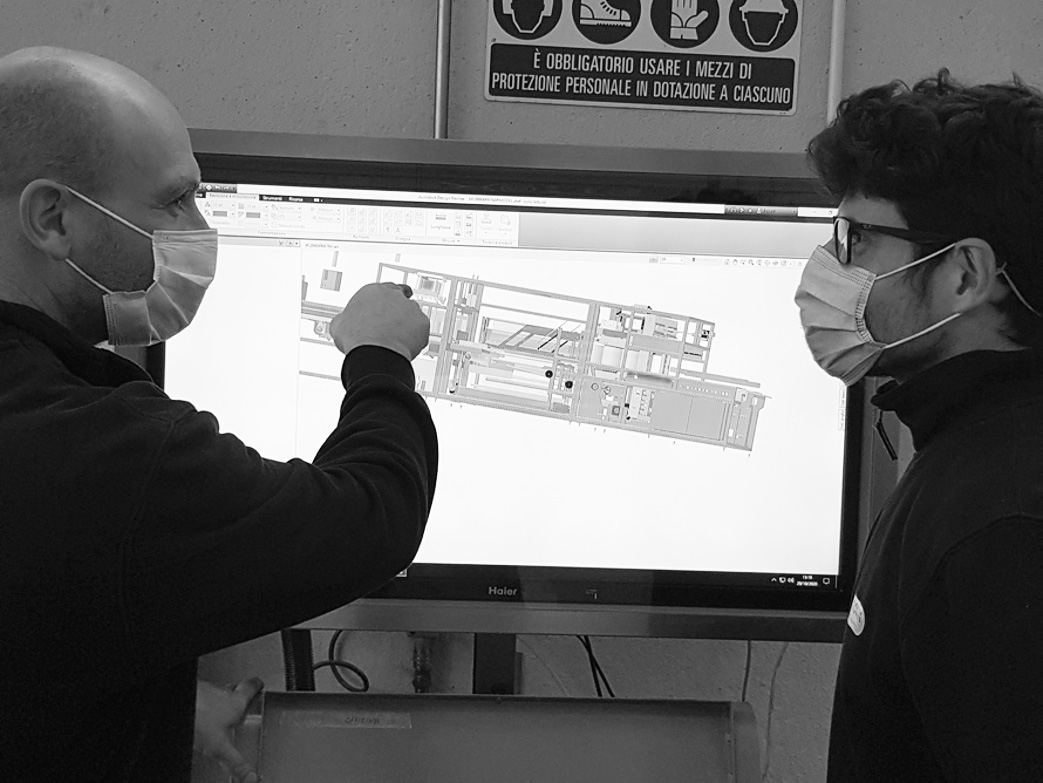

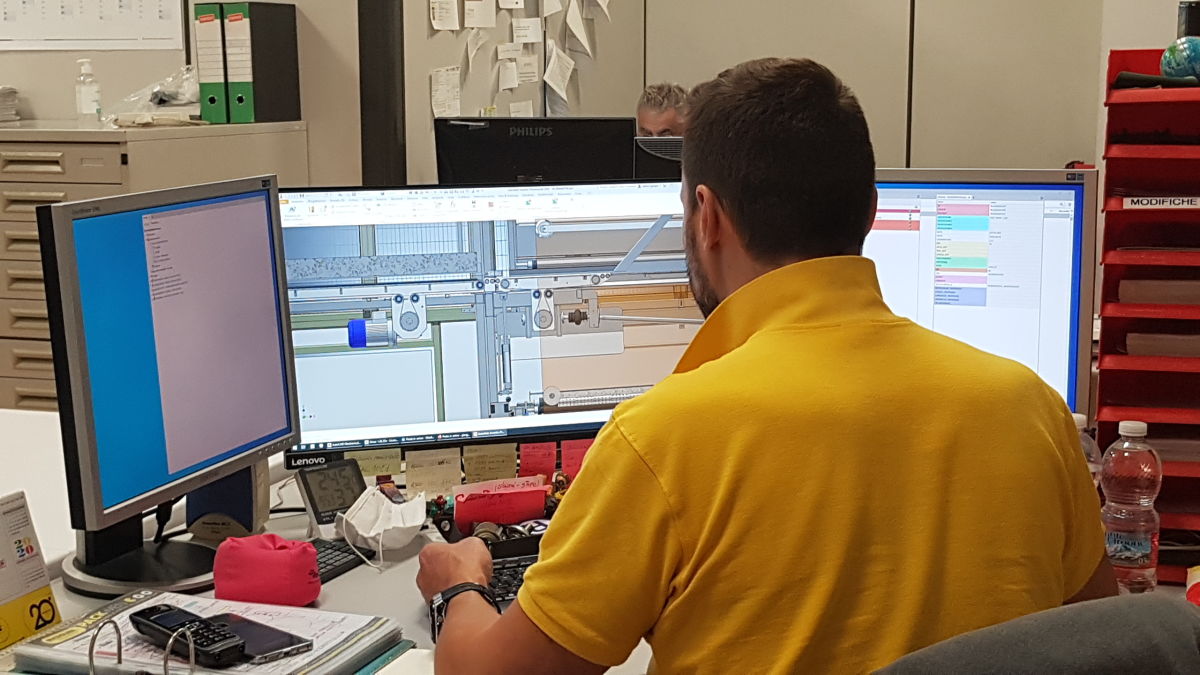

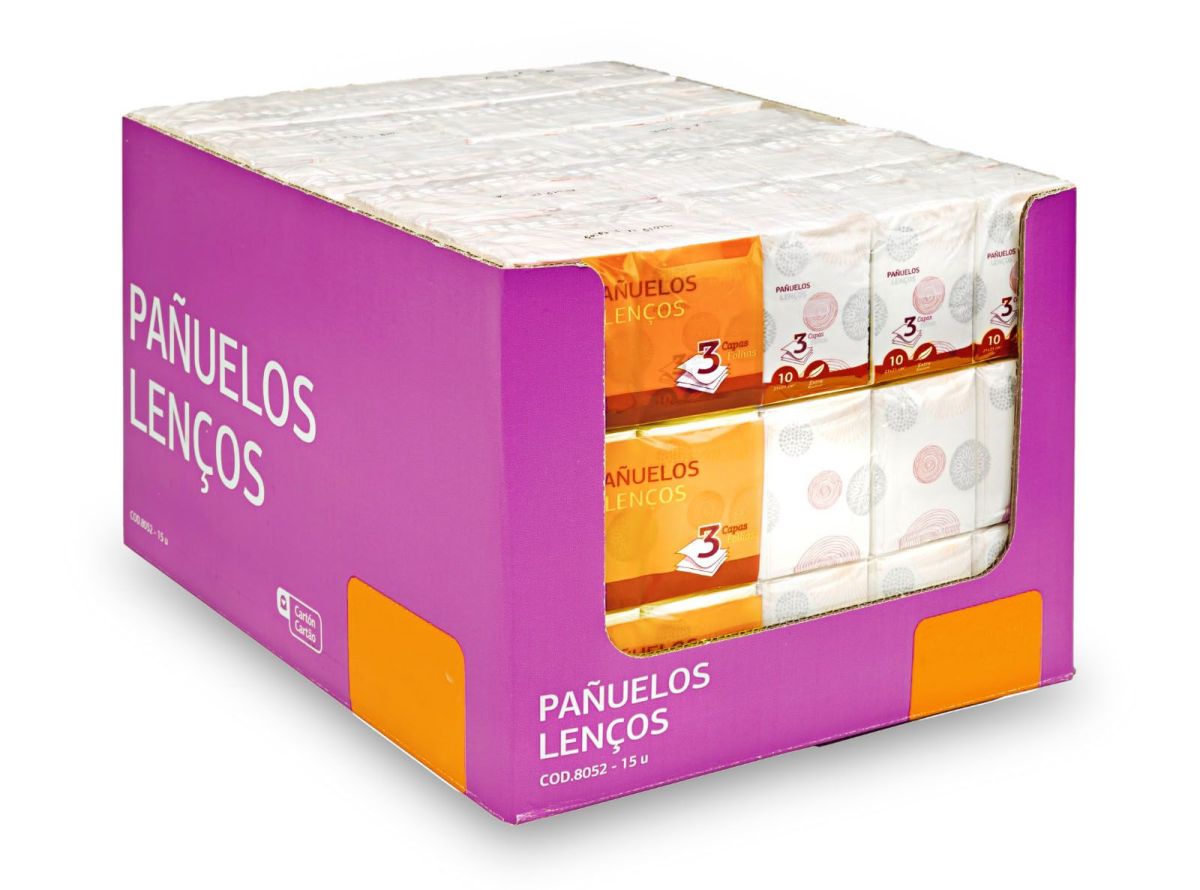

MICROLINE packaging & automation: high speed, great flexibility, excellent productivity.

Microline is specialised in the manufacture of automatic end-of-line packaging machines. Thanks to its know-how in the tissue sector, over time it has created dedicated machines that fully satisfy the demands of this particular market... Read more

.jpg)

-2.jpg)

-2.jpg)

-2.jpg)

-2.jpg)

.jpg)