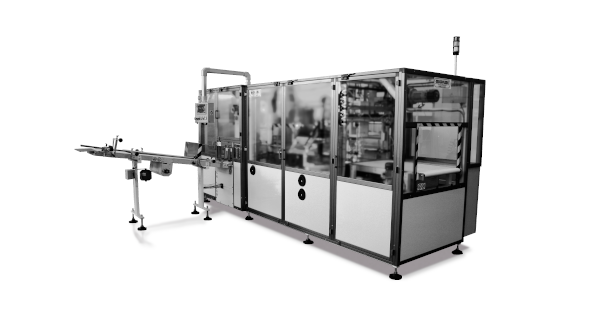

The ECO WRAP 1050 is a multi-pack bundler for AFH rolls. The products coming from the saw/wrapping machine are fed to the machine by a system of conveyors that orient and convey them inside the machine in a single row by means of a system that arranges them in the desired configuration. The products are then placed in the lifting unit (for layering, if required) and placed in the bag. The bag is then closed during the next stage. This is done by cutting the film crosswise and folding the edges inside the bag.

The ECO WRAP 1050 machine is electronically controlled by a PLC control system. Any operator can easily use the HMI panel (touch-screen), to set the size parameters directly and save them in recipes that can be recalled at each production change.

This machine can pack up to 6 bags per minute in a wide range of configurations, without the need for a shrink tunnel. The ECO WRAP 1050 is also very efficient and saves on packaging material, as it produces no waste during the wrapping process. Energy consumption is also low: the bundler creates tight-fitting bags that do not necessarily require the use of a shrink tunnel.

Lastly, the one-piece design allows the machine to be quickly commissioned and installed. It can be rapidly configured for start-up. This avoids prolonged line stoppages and improves production efficiency.