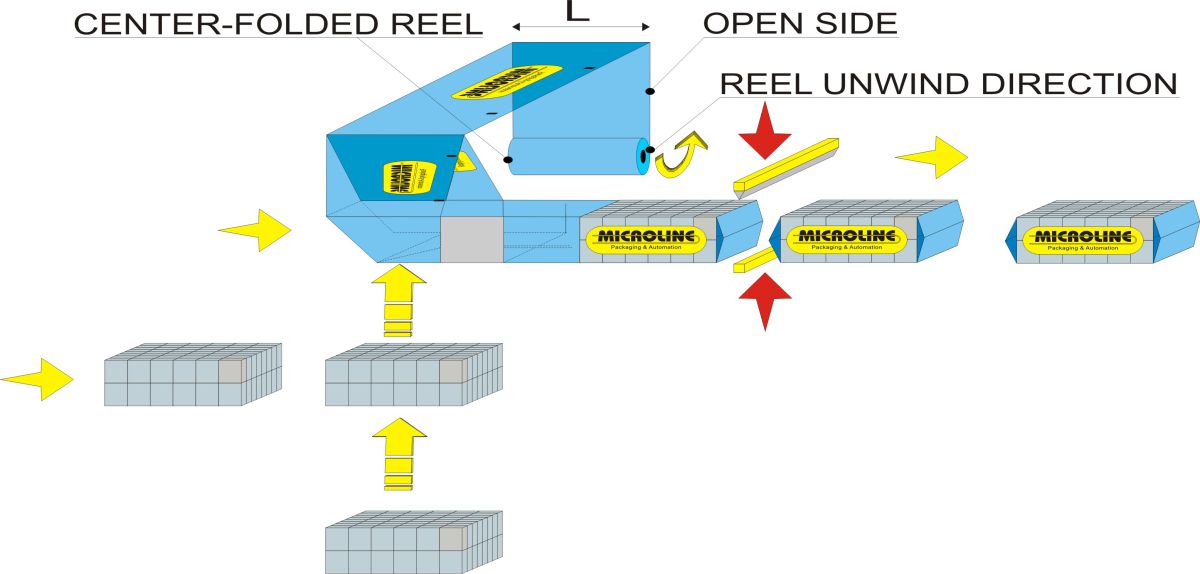

FLOW WRAP 1000 is a multi-pack wrapper. The products (napkins or towels) coming from the upstream wrapper are fed to the machine by a system of conveyors that orient and convey them in multiple rows; then they are counted and arranged according to the desired collation. The products are subsequently inserted into the bag, which is then closed by cutting the film crosswise and folding the edges inside the package.

FLOW WRAP 1000 is the first machine in this market segment to be completely controlled by a servo-motor system.

Thanks to this solution both size changeovers and general machine functions can all be easily controlled from the touch-screen panel.

This machine can pack up to 18 bags per minute, without the need for a shrink tunnel, in all configurations demanded by the market.

Its innovative conception brings advantages in the packaging process, in terms of both consumption of materials and energy savings: the flow wrapper creates tight fitting bags that do not necessarily require the use of a shrink tunnel.