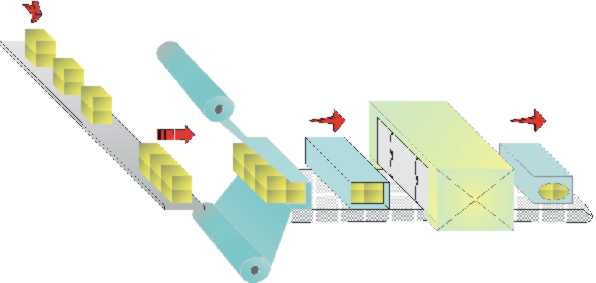

AUTOMATIC SHRINK WRAPPER / BUNDLER WITH RIGHT-ANGLED INFEED

Automatic shrink-wrapping machine equipped with a motor-driven feed conveyor set at a right angle, multi-line grouper, wrapping/sealing station and shrinking tunnel. Machine suitable for grouping, shrink wrapping products like bags, boxes, jars, bottles, etc. with heat-sealable, heat-shrinkable film.

- Shrink wrapper available in different versions;

- Multi-line version (2 – 3 lines);

- Possibility of producing a bundle with a handle or closed with self-sealing of the film.

- Designed for medium-low production rates, up to 20 packages per minute depending on size requirements.

Specifications:

- Painted welded steel tubular frame

- Modular inverter-controlled multi-line feed conveyor with adjustable product guides

- Pneumatic device for blocking products during their introduction

- Product presence monitored with sensors to enable product transfer

- Intermediate bundle-forming station

- Pneumatic pusher for bundle forming and final push beyond the sealing bar

- Motor-driven reel unwinding units with automatic film recovery

- Pneumatic sealing bar for film cutting and sealing. Maximum height for passage of the product up to 380 mm

- Sealing without emission of fumes

- Height-adjustable pneumatic package presser

- Metal mesh tunnel conveyor system with speed adjustment via inverter

- Ventilated tunnel with differentiated dual thermal insulation designed to optimize heat retention

- Electric control panel installed on the left or right side, complete with PLC and HMI panel

- Extremely fast size changeovers

- Optional features: bundle cooling device at the tunnel outlet, edge-pressing unit, residue removal, tunnel evacuation, remote service, etc.