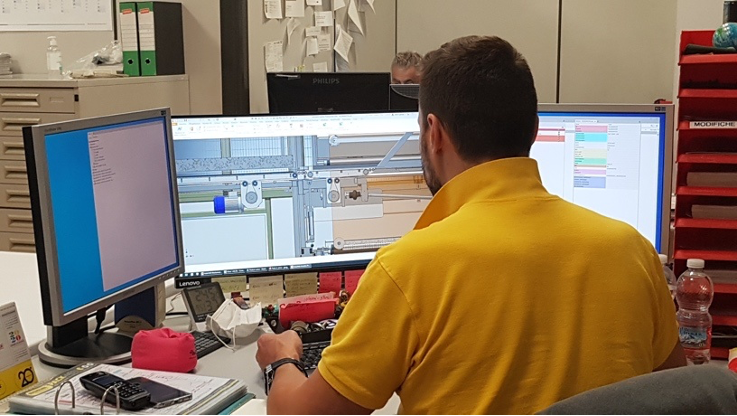

Microline’s digital strategy

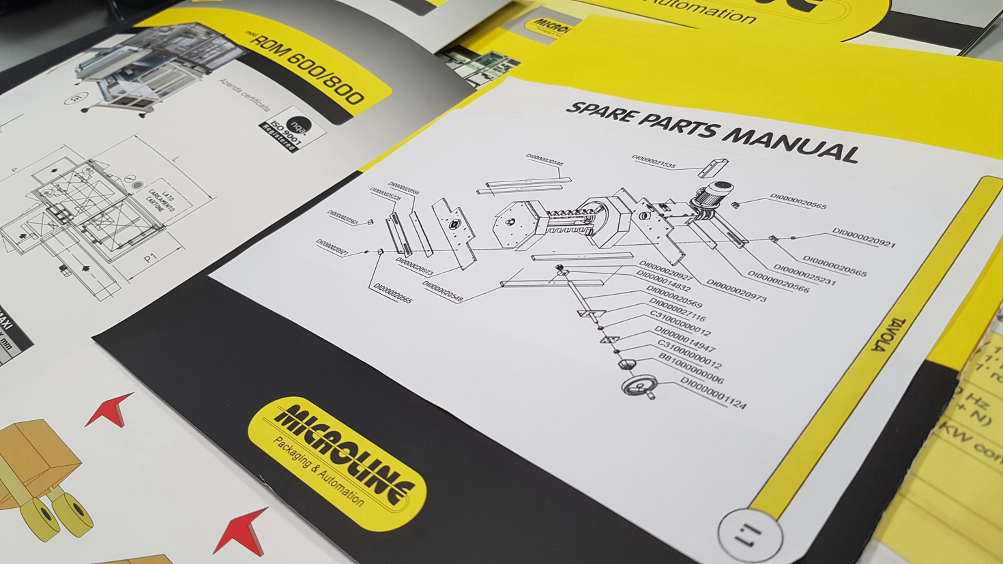

The design and marketing of our machines proceeds alongside the process of digital transformation undertaken by the company in recent years. This new approach involves various areas, from virtual FATs to remote diagnostics. At the same time, it continues to develop instruments such as forecasting software, able to predict the machines’ future needs in terms of maintenance, which simultaneously optimises operations and efficiency. Lastly, this year saw the adoption, across the entire product line-up, of an HMI panel featuring particularly advanced functions. It is human-machine interface boasting extremely user-friendly operating logics, to make controlling the machine even simpler. The new panels also help improve the maintenance of the machines, as they are able to transmit their different routine and non-routine maintenance needs, and therefore facilitate the ordering and replacement of spare parts.