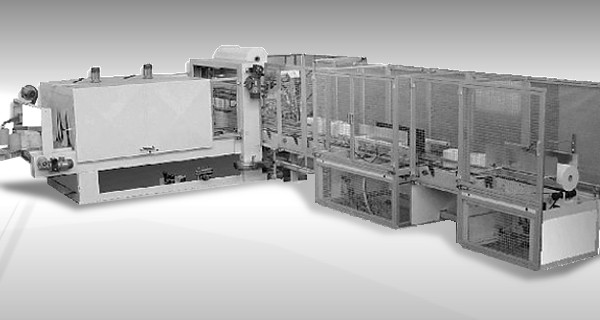

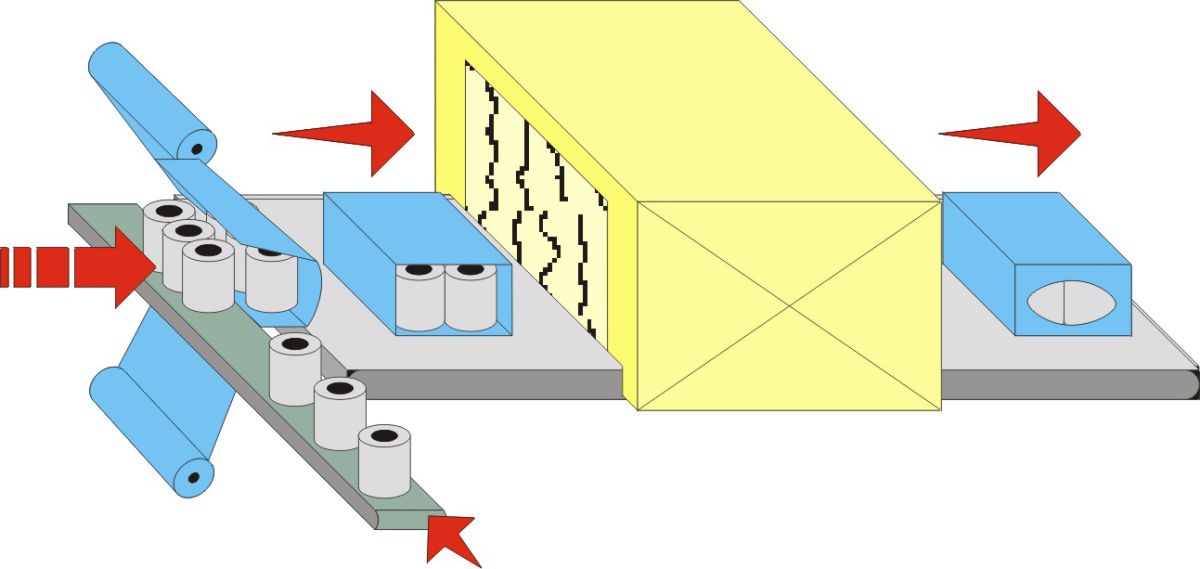

This is the traditional shrink-wrapping machine, suitable for collating and shrink-wrapping industrial-purpose paper rolls with plastic film. The film in excess on the sides of the pack forms the edges that overlap and close the bundle laterally during heat shrinking.

The products coming from the saw are upended (the core is put in a vertical position by a roll upender), if necessary divided into several lines (switching system), arranged according to the desired collation and pushed into the wrapping station.

The packs are then separated while passing through the wrapping/ sealing station and subsequently conveyed inside a shrink tunnel/oven, where the heated film shrinks around the product and adheres to it.