The FAST WRAP 1250 is a multi-packing flow wrapper designed to arrange, collate and place industrial AFH-type paper rolls in bags.

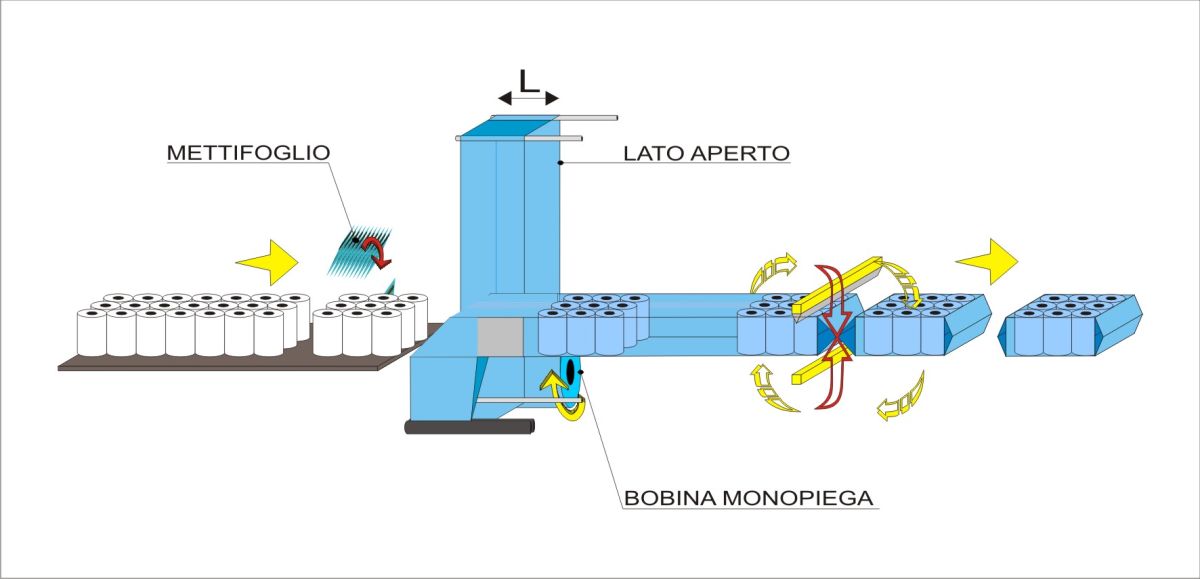

The rolls coming from the saw are fed by a system of conveyors that orient and transfer them to the machine in multiple rows; they are then counted and arranged according to the desired configuration. The rolls are picked up from the conveyor belt and put "in phase" to allow the wrapping cycle to begin.

In the FAST WRAP 1250, wrapping using a centre-folded reel is achieved by placing the film around the prearranged rolls, and then joining and subsequently sealing the edges at the top of the bag. The pack is then transferred to the transversal seal station where packs are parted. Front and rear seals are done by a hot bar self-centring cross system.

With the FAST WRAP 1250 roll packs can be customised with glued label insertion or pre-printed film.

With this packaging process, FAST WRAP 1250 film consumption is approximately 25% lower compared with other wrappers available on the market.

The wrapping process does not generate wrapping material scraps or rejects, consequently cutting disposal costs and reducing shrinking temperatures.

Given these multiple advantages, the cost of the entire wrapping process is 30-35% lower.

The FAST WRAP 1250 is the first machine to be completely controlled by an electronic servo-motor system. Thanks to this solution, both size change-overs and general machine functions can all be easily controlled from the touch-screen panel.

The main features of the FAST WRAP 1250 are as follows:

- continuous cycle flow wrapper;

- production rates of up to 25 packages per minute;

- management of all products exiting an AFH roll saw;

- wide range of use;

- fully closed bundles (with or without shrinking tunnel);

- total use of the packaging roll without film trimmings;

- modular design and electronic control of the entire system using electronic cam synchronised servomotors;

- inner label applicator (glossy paper) for sizes from A4 to A5;

- size change-over is carried out by means of the control panel, manual adjustments are done by means of a hand-wheel with numeric position indicator, and film guides can be replaced without tools.